3. IPU-POD DA configurations

It is possible to build a number of IPU-POD DA configurations, based on the different numbers of IPU-M2000s, rack types and PDU types. Minimum requirements for the rack environment and PDUs are given in the next section. Fig. 3.1 and Fig. 3.2 illustrate the range of system configurations: others are also possible.

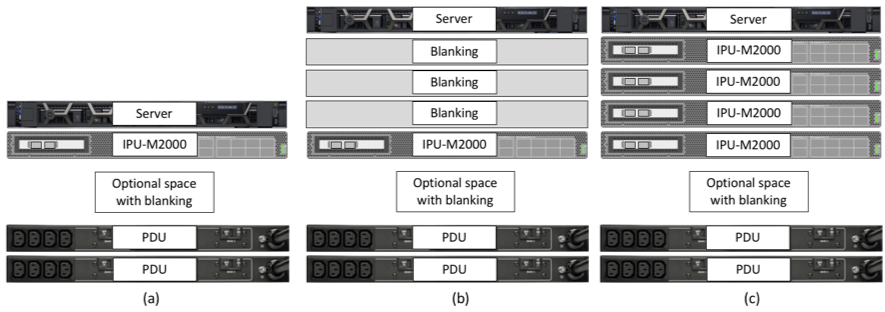

Fig. 3.1 Direct attach configurations (a-c)

System (a) is a baseline IPU‑POD4 DA configuration, shown with redundant horizontally rack-mounted PDUs. System (b) is functionally the same IPU‑POD4 DA configuration where space has been allowed between the first IPU-M2000 and the server for future expansion up to an IPU‑POD16 DA system. System (c) is a baseline IPU‑POD16 DA configuration, with redundant horizontally rack-mounted PDUs. In all cases, power cabling to the PDUs can sometimes be made easier by allowing space between the lowest IPU-M2000 and the PDUs.

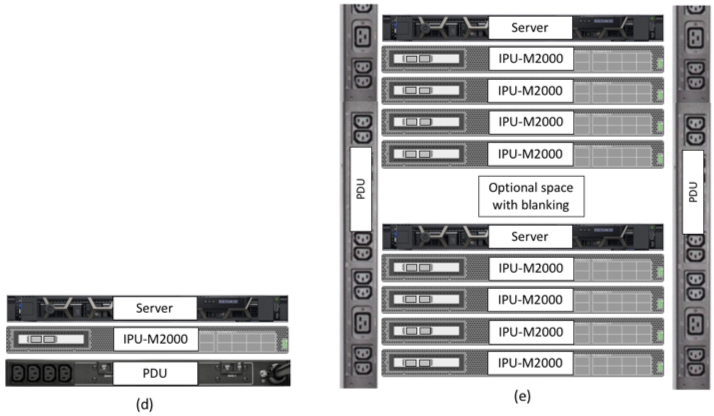

Fig. 3.2 Direct attach configurations (d-e)

Systems (d) and (e) show the extremes for IPU‑POD4 and IPU‑POD16 DA configurations. System (d) is a minimally configured IPU‑POD4 DA system using just one horizontally mounted PDU. While this is not recommended in production deployments due to lack of redundancy, it could be appropriate for small development systems. System (e) shows a larger rack deployment where more than one IPU‑POD16 DA system is deployed. In this case, it may be more effective to use two higher power vertically mounted PDUs to supply more than one IPU‑POD16 DA system. Given power and cooling, it is possible to build racks containing 4 or more IPU‑POD16 DA systems powered by such vertical PDUs.